MATERIAL QUALITY CONTROL

Descrizione

Changes in materials behavior can cause variation in your process and lead to defects, delays, rework, waste, and more.

Take out any guesswork by taking materials measurements before and during your process, to ensure consistency.

Process traceability

Reduction of waste

Quick measurements

Guaranteed repeatability

Discover the range of our solution of Material Quality Control

TECHNICAL DATA

Vision mark-1:

- Quality control before printing

- Monitoring the quality of the pasta during the process

- Prolongs the life of the stencil

- Fast and small samples

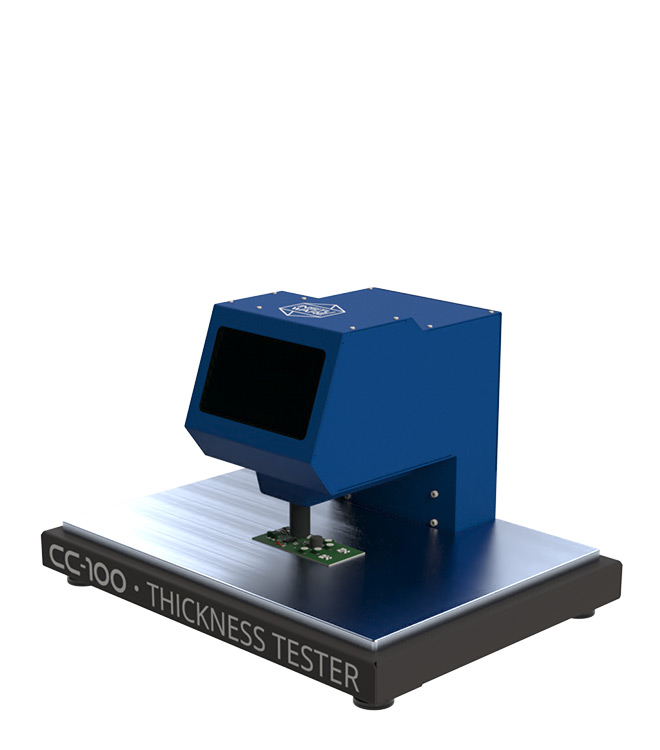

CC100:

- Non-conductive and non-contact conformal coating thickness measurements

- Automatically mix the soldering paste jars making them immediately suitable for use

- Real time monitoring

- Reduced preparation time

SS100:

- High accuracy (-2um)

- Fast process ( < 1 second)

- Works with different types of materials: silicone, acrylic, polyurethane, epoxy resin etc…